Micro Hole Perforated Metal Production Process

After our detailed introduction of the perforated metal in our previous article, we have know that for regular pattern perforated metal we have punching machine to finish it, and for irregular patterns, we have laser cut machine to finish it.

but there are some sizes with regular patterns, and the hole are very small, maybe 0.5mm or smaller. which process method we should choose?

At this time, we will choose etching process.

Then what sizes should be finished by etching process?

| Material: | Iron or stainless steel, stainless steel is the most popular material. |

| Thickness: | 鈮?mm |

| Width: | 鈮?00mm |

| Length: | 鈮?00mm |

| Hole diameter: | 鈮?mm |

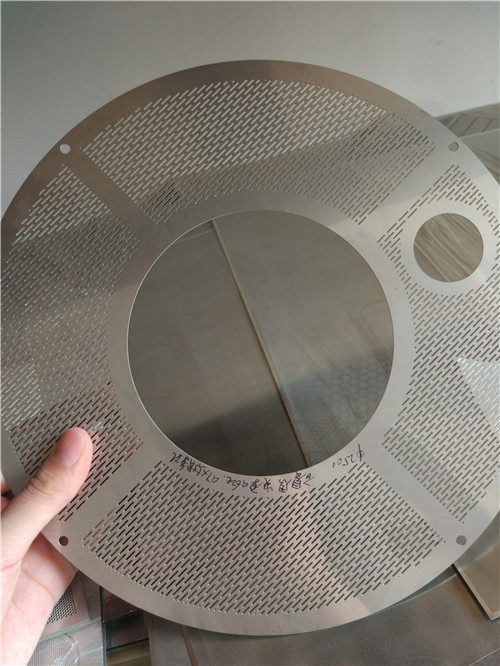

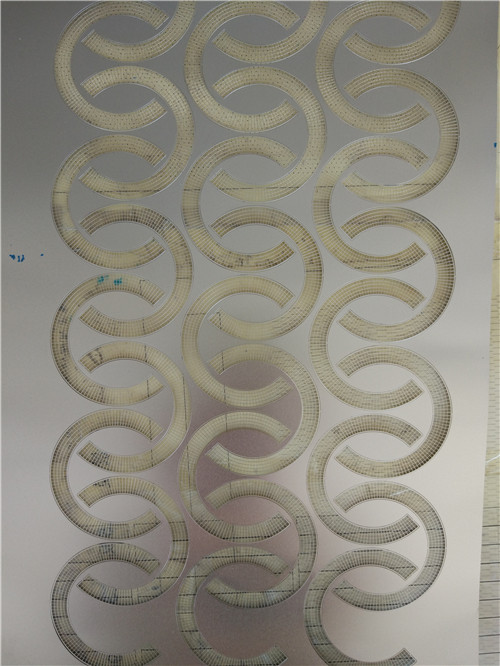

Etching products show.

|

|

|

|

|

|

The advantages of the etching Mesh

-

the surface is very smooth and clear, nor burs not stains.

-

the tolerance of the hole size and the panel dimension is very small, we can control it in 0.05mm.

-

both the hole pattern and panel dimension could finished once.

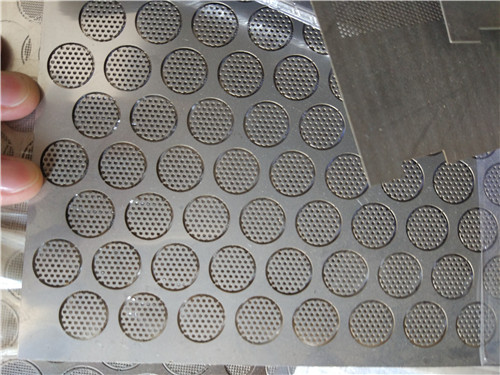

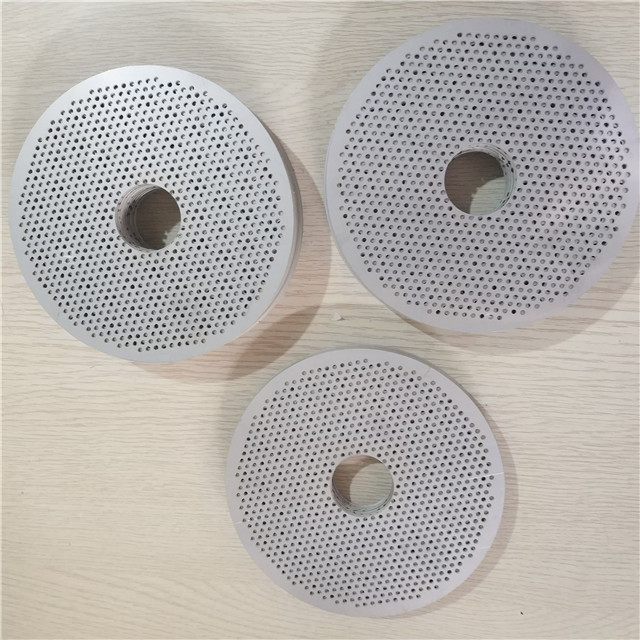

we just finished one order from Australia customer, it is round hole pattern and the dimensions is also round, with hollow in the center.

|

|

|

Etching perforated mesh is widely as filter mesh, and other high requirement equipments.

If you are also in need of it, contact us.

Spring

sales5@huijinwiremesh.com

+8615333185479

Post time: Jan-15-2023