Expanded metal is a metal mesh manufactured from a solid metal sheet or coil of carbon steel, stainless steel, aluminum, galvanizes steel or other alloys that is stretchable.

Many customers think that the expanded metal is made by punching. In fact, the expanded metal manufacturing process is that the expanding machine moves back and forth to cut the sheet in alternating cuts for a specific shape. In the process of cutting and stretching, there is no material waste.

The expanding machine is fitted with a knife which determines pattern for the mesh. Several different knife patterns can be used to cut the sheet into different shapes and sizes. There are many shapes like diamond, circle, oval, square, hexagonal, and the diamond shape is the most common option. As the metal is fed through the expanding machine, it is cut and stretched simultaneously using a pressured slitting and stretching process.To ensure a consistent pattern, the expanding machine is programmed or operated manually when the metal is fed through. The purpose of creating expanded metal is to stretch it. You only need a small piece of metal for this process.

As the process starts with a small sheet of steel and results in the production of a large mesh, it is lightweight, cost-effective and environment friendly. While still allowing airflow and light in, expanded metal is very strong and durable. The versatility of expanded metal also widens the opportunity for usage. Expanded metal is used in projects involving architecture, agriculture, horticulture, transportation and art installation.

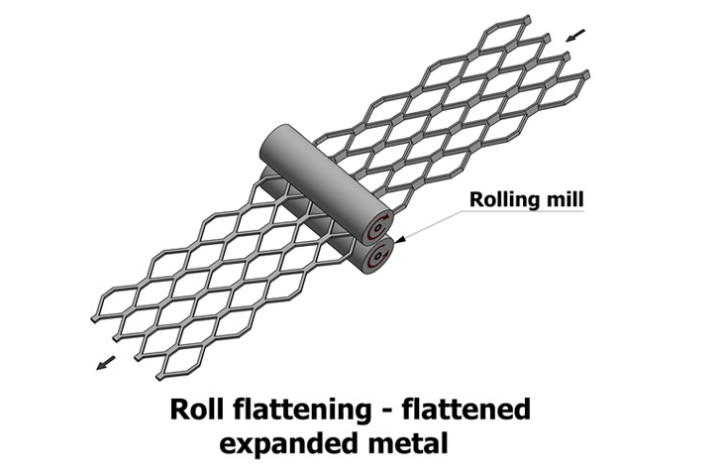

Flattened expanded metal is produced by cold rolling standard expanded metal to flatten it. This process makes the mesh mesh surface more smooth and thickness thinner. So Flattened expanded metal is about 5% lighter than the standard expanded metal.

Standard expanded metal is often used to provide a rigid, raised and slip-resistant surface. While when a smooth surface is required, you can choose flattened expanded metal.

Post time: Jan-15-2023